Installing the Borg Warner R 10 Overdrive in the torque tube.

Cut out flanges to fit both ends of the overdrive from 3/4" plate,and cut the center holes to accept your torque tube.

You'll need to gather a coupler for the input and output shafts. Some machine work will likely be required to fit them to your shafts. The rear one will be welded to the drive line and a seal will need to be fit at that point so your overdrive lube will not run to the rear end. The output shaft will slide into the fixed coupler on the rear driveline. This will allow easy installation of the complete unit. Weld the front coupler to the front portion of the drive line. This end will be pinned to the input shaft on the overdrive unit so it doesn't travel forward.

You will need to install a fairly large vent out the top of the overdrive unit, similar to the rear end vent but more like a 1/4" to 3/8" vent. The overdrive will generate substantial heat and therefore the use of synthetic gear lube is recommended.

The custom, extended speedometer cable will need to be a sealed casing as the oil will travel up the cable. Cap the speedo output on your transmission.

You will need an overdrive relay unit. I used a Ford or Merc. relay. The relay is triggered by a governor on the overdrive unit, that grounds the trigger circuit at 25 mph and sends power to the solenoid by 10 gauge wire, which will allow it to go into overdrive mode if your cable control is at the "in" position.

I used a Packard cable as I figured it was a little longer so as to compensate for the overdrive being back in the middle of the torque tube. I formed the mounting bracket for the cable so that it slides down onto my shifter and acts as a tapered, compression fit.

I use a toggle switch to break the governor circuit, to the relay, so I can split gears. Cable in, switch on, 1st- clutch- 2nd- throttle off clutch in- 2nd over throttle and switch off, throttle off for 3rd-throttle- switch on, throttle off for 3rd overdrive, now you're cookin'.

I use clutch for the second over but not for 3rd over. It's a little to snappy or violent for second over in my opinion without the clutch. This will get you down the road in a "wow" fashion. At least that is what everyone says that rides in my truck.

Get very accustomed to the shifting before you try to speed shift.

You must not pull the cable out of gear when you are in overdrive mode and you must not engage cable when the solenoid is engaged.

It is best to not move your cable when in motion, until you have very good understanding of how the system works. I take it out of cable overdrive after I have switched it off and come out of solenoid overdrive and snugged the gears forward.

If you are not completely confident with your understanding of the shifting sequence, it is just safe to not move the cable when in motion. The only reason to pull the cable out when in motion is to take it out of "free wheel". Normally it was not designed to do that and had a built in safety device.

I have put 35,000 miles on mine at this point and it is still working great. There were trials and errors but if you follow my directions here, you should have a fail safe installation.

Doug's Classic Coachworks

RestoRodsToGo.com

1957 Nash Metropolitan Restoration

This 1957 Nash Metropolitan restoration started out a pretty nice car. It did have minor rust issues as is expected of a car that is over 50 years old. Walt Johnsen brought the car to me for the sheet metal reconstruction and surfacing, and I got it in initial primer surfacer as well. Walt took it from there, with the assistance of "Hutch" and in his normal fashion, completed undoubtedly one of the nicest Metros, period. (Not to use the term "period" as it has been used by our current "fearless leader").

The fit on these Metropolitans was not the best. The gaps varied quite a bit from the factory. As long as things closed without interference, it seamed "good enough". I made a choice to refine the gaps to give it a more crisp appearance.

As a result of my reconstruction, fit of the sheet metal components, and Walt's surfacing and finishing, as well as his attention to detail in the re assembly of this 1957 Nash Metropolitan, it was the recipient of "Best in Class Award" for 1949-1959 Domestic automobile at 2013 Forest Grove Concours d' Elegance.

The fit on these Metropolitans was not the best. The gaps varied quite a bit from the factory. As long as things closed without interference, it seamed "good enough". I made a choice to refine the gaps to give it a more crisp appearance.

As a result of my reconstruction, fit of the sheet metal components, and Walt's surfacing and finishing, as well as his attention to detail in the re assembly of this 1957 Nash Metropolitan, it was the recipient of "Best in Class Award" for 1949-1959 Domestic automobile at 2013 Forest Grove Concours d' Elegance.

Doug,

On the 1939 Chevrolet, you said you put highway gears in, did you use the original housing? If yes, how did you do it?

Thanks, Victor

Hello Victor,

We actually used the 1940 rear end and adapted the 39 drive line to that because we had a set of NOS gears for the 40. I recall a little machine work to make it happen with the drive line.

It may be possible to use an aftermarket, early replacement universal joint rear half with the original front half in order to couple the 40 driveline. I know that works for the trucks. Some of the better quality joints won't work because they were the needle bearing style, instead of the early style, solid bearing type. Finding gears is the hard part. I don't know if there are any new gear manufacturers. Sometimes those are noisy and inferior quality. I installed a Borg Warner Overdrive in my truck. It works very well. That requires a lot more machine work and engineering. I have another case and extra gear set for the OD.

There are some options for you to think about if any of that interests you. I think I have one of the universal joints that I spoke of earlier too.

Thanks for asking, Doug

1931 Bentley 8 Litre Sedan 1929 Isotta Fraschini

Classic Car Restoration on cars like the 1931 Bentley 8 Litre Sedan and the Isotta Fraschini was going strong in the 1980s and 1990s.

I was working with Walt Johnsen back then and these two particular cars were among those that we restored. His business was "The Auto Shop" on Bainbridge Island, Washington. The 1931 8 Litre Bentley was a complete restoration that we did. Terry Foss was apprenticing with us at the time.

Dave Loeington did the Mechanical and wiring, Dave had to manufacture a lot of the components to get this car up and running in the fashion that Bentleys are known for.

Don Volgosang took care of the bright work and chrome trim,

Kirk Person who was the best of the best in his trade, did the Upholstery. He was an all around, nice, easy going guy. It was a tremendous loss to the car community when he passed.

The Isotta Fraschini was more of a cosmetic, or body restoration in "The Auto Shop". I did make a new fuel tank for the car, in the original fashion, with the leaded seams etc. The 1929 Isotta-Fraschini is a Tipo 8A with limousine bodywork by Castagna of Milan. The marque and the coachbuilder were a great combination among European luxury cars. This is one of the very few Isotta-Fraschinis to have come to the United State in the 30s. The Tipo 8A's massive straight-eight, displacing 7,370cc, was just under 450 cubic inches and produced 110hp.

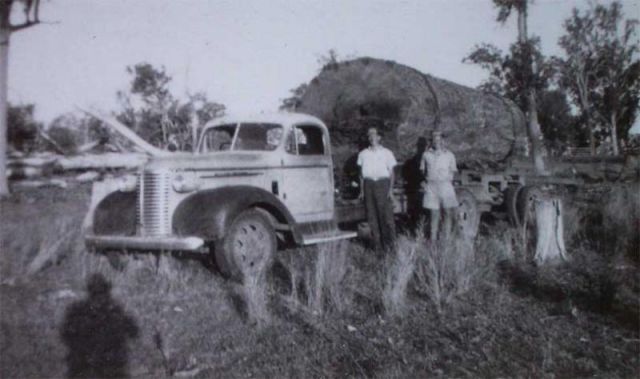

Both of these cars were owned by Al McEwan and Dick Hooper of Seattle area. They have both subsequently been sold. Jay Leno purchased the 1931 8 Litre Bently and the Isotta Fraschini went to Mort Bullock, pictured here from left to right, Al, Mort, And Dick, standing in front of the Isotta Fraschini.

We didn't have many pictures of the Bentley 8 Litre, but this one is interesting in that it shows the turnbuckle system on the bottom of the frame. Over time a large car like this would tend to sag from all the weight. This system would correct sag. The top was covered with leather that had to come from a very large bovine.

I was working with Walt Johnsen back then and these two particular cars were among those that we restored. His business was "The Auto Shop" on Bainbridge Island, Washington. The 1931 8 Litre Bentley was a complete restoration that we did. Terry Foss was apprenticing with us at the time.

Dave Loeington did the Mechanical and wiring, Dave had to manufacture a lot of the components to get this car up and running in the fashion that Bentleys are known for.

Don Volgosang took care of the bright work and chrome trim,

Kirk Person who was the best of the best in his trade, did the Upholstery. He was an all around, nice, easy going guy. It was a tremendous loss to the car community when he passed.

The Isotta Fraschini was more of a cosmetic, or body restoration in "The Auto Shop". I did make a new fuel tank for the car, in the original fashion, with the leaded seams etc. The 1929 Isotta-Fraschini is a Tipo 8A with limousine bodywork by Castagna of Milan. The marque and the coachbuilder were a great combination among European luxury cars. This is one of the very few Isotta-Fraschinis to have come to the United State in the 30s. The Tipo 8A's massive straight-eight, displacing 7,370cc, was just under 450 cubic inches and produced 110hp.

Both of these cars were owned by Al McEwan and Dick Hooper of Seattle area. They have both subsequently been sold. Jay Leno purchased the 1931 8 Litre Bently and the Isotta Fraschini went to Mort Bullock, pictured here from left to right, Al, Mort, And Dick, standing in front of the Isotta Fraschini.

We didn't have many pictures of the Bentley 8 Litre, but this one is interesting in that it shows the turnbuckle system on the bottom of the frame. Over time a large car like this would tend to sag from all the weight. This system would correct sag. The top was covered with leather that had to come from a very large bovine.

Here is a picture of the Bentley in Suite 200 in Kirkland before Jay Leno took ownership.

Labels:

Classic Car Show,

Classic Cars,

Restorations by Doug

1957 Chevrolet Belair Fuel Injected, Restoration

1957 Chevrolet Fuel Injected Belair original matching numbers cars are few and far between. Because this car is a complete original fuelie, it was worthy of an extensive, first class restoration. Being an original black car makes it even more desirable, but being black, requires special talent in both sheet metal work and final finish.

Walt Johnsen and I worked together back in the late 80's and early 90's, when we were restoring Classic Cars and showing them in the west coast Concours d' Elegance events at Pebble Beach and Forest Grove, consistently receiving "Best in Class" awards and in 93 had the Murphy Bodied Duesenberg that was very close runner up for "Best of Show" at Pebble Beach.

The two of us have always complimented each others exception talents and abilities. Walt is the best re finisher that I know. I have been in the automotive body and restoration business for over 45 years, just to put my comment into perspective. Walt has a keen eye for attention to detail, and again it shows in his completed 1957 Fuel Injected Belair.

Walt Johnsen and I worked together back in the late 80's and early 90's, when we were restoring Classic Cars and showing them in the west coast Concours d' Elegance events at Pebble Beach and Forest Grove, consistently receiving "Best in Class" awards and in 93 had the Murphy Bodied Duesenberg that was very close runner up for "Best of Show" at Pebble Beach.

The two of us have always complimented each others exception talents and abilities. Walt is the best re finisher that I know. I have been in the automotive body and restoration business for over 45 years, just to put my comment into perspective. Walt has a keen eye for attention to detail, and again it shows in his completed 1957 Fuel Injected Belair.

Overdrive upgrade in your Vintage Automobile

Doug,

I’m working on a 1936 Dodge (P-24 Engine, original transmission). Planning to use this as a DRIVER ... Local Car Shows and Cruise In’s. I’d like to be able to cruise at current road speeds (55-60). Can’t do it with stock gearing. The engine’s ‘sweet spot’ is around 45 MPH. Any suggestions you have will be appreciated but would really like information and sources for an original, period correct, floor shift Borg Warner (?) OVERDRIVE or Overdrive Transmission. Thanks in advance for your help and counsel.

Bill

Hello Bill,

My suggestion would be to research the later Chrysler Corp. 3 speed overdrive transmissions. I seriously doubt that you will find anything that would be date correct to your 36 Dodge that would give you the gear ratio that you are seeking. I am not that familiar with the Chrysler options and or interchangeability. It may be that you will have to mount an overdrive separately, as I did in my 37 Chevy Pickup.

Yours should be easier to install if I am correct in assuming that you have an open drive line situation in your Dodge.

If I can be of further assistance, let me know.

Doug

Econoline Visor 1963 Ford Custom

1960s Econoline Van outside Visor was never offered. My friend at Doghouse Powder Coating wanted a visor for his van, so I made one for him. The screws in it are temporary, and will be replaced with stainless finish screws. If you're interested in a custom made visor for your vehicle, please contact Doug's Classic Coachworks.

235 Chevrolet Stove Bolt Split Exhaust Manifold

Dual Exhaust 235 261 Chevrolet Stove Bolt Six, Split Manifold. Here is another example of a custom split manifold. I think this is the best looking one yet that has come out of Doug's Classic Coachworks. The original manifold did have some East Coast rust pitting but a tight shaft on the heat riser because it is off a low mileage truck.

HOT RODS and CLASSIC CAR RESTORATION SEQUIM WASHINGTON

Car restoration, from rust repair and wreck repair all the way to Concours d' Elegance award winning, complete restorations, is what I have been doing since 1969. Completely disassembling and reassembling of bodies has been performed by me many times. Wooden bodied cars as well as all metal cars are included in my list of accomplishment. Best of show awards, magazine articles and many best in class awards have been presented to owners of cars that I have had a large part in the restoration of.

Hot Rod building is something I find great satisfaction in. Unlike most, I make a big effort to maintain a "Theme" when building a car. In other words, if I'm building a 1950's style Hot Rod, it will be built with 1950's and prior parts. Naturally, those parts will be restored to top notch condition, because Resto RodsTo Go stands for Hot Rods that can be driven daily. One of the things that makes these cars so special is that they are "timeless" and will maintain their desirability through time, unlike the fad cars that are being built with the "off the shelf parts", that are obsolete next year.

Taking advantage of the work that those highly skilled designers that worked for GM, Ford, and Chrysler seems to make a lot more sense to me than using the machine shop designed billet steering wheels, etc and industrial gauges, that are usually used in Street Rod building.

If you set up your steering column properly, you don't need to install that tilt column, but rather use a cool early column and wheel that has real character, and not that Kubota tractor look.

I would much rather lift the hood to see an early Hemi or an early fuel injected 283 or dual quad 265 Chevy. Generic chrome becomes pretty bland when up against a tasteful paint scheme under the hood like the factory designers developed.

Hot Rod building is something I find great satisfaction in. Unlike most, I make a big effort to maintain a "Theme" when building a car. In other words, if I'm building a 1950's style Hot Rod, it will be built with 1950's and prior parts. Naturally, those parts will be restored to top notch condition, because Resto RodsTo Go stands for Hot Rods that can be driven daily. One of the things that makes these cars so special is that they are "timeless" and will maintain their desirability through time, unlike the fad cars that are being built with the "off the shelf parts", that are obsolete next year.

Taking advantage of the work that those highly skilled designers that worked for GM, Ford, and Chrysler seems to make a lot more sense to me than using the machine shop designed billet steering wheels, etc and industrial gauges, that are usually used in Street Rod building.

If you set up your steering column properly, you don't need to install that tilt column, but rather use a cool early column and wheel that has real character, and not that Kubota tractor look.

I would much rather lift the hood to see an early Hemi or an early fuel injected 283 or dual quad 265 Chevy. Generic chrome becomes pretty bland when up against a tasteful paint scheme under the hood like the factory designers developed.

Replacing Floor Pans and Rocker Panels with originals.

Hi Doug,

I'm restoring a 61 Cadillac convertible. Floor pan. Bracing and rockers are rotted out so I have a 62 Cadillac 2 door with a good floor etc., that I'm intending to cut out in one piece to replace the convertible floor pan etc. Assuming the floors are identical which I believe they are.

I was a body and fender man 40 years ago, so I hope I haven't forgotten too much. Of course dimensions and alignment are critical. Any advice would be very much appreciated.

My other hobby projects are a 74 Corvette, 68 Plymouth, 55 Imperial, 59 Imperial and another 62 Cadillac. All 2 doors.

Thanks very much.

Best Regards,

Gary

Kingston, WA

Hi Gary,

Taking it apart at the original factory seams is the way to go. They make some real good spot weld cutters/drills now, that we just didn't have 40 years ago. Also, we are using die grinders with cut off wheels, to cut welds. It used to be that we took everything apart with an air chisel, back in the late 60s and 70s. Those are used much less now as it was so easy to damage your project with the chisel. We also have a weld through primer now for the seams that consists of a high zinc content. This primer does a fantastic job of holding down the corrosion in your welded seams. It does make plug welding more difficult, but the benefit outweighs the negative.

Once you get your floor pan and rocker assemblies removed at the proper seams, clean them thoroughly and punch holes for your spot/plug welds, keeping in mind the easiest side to dress your welds when finished, assuming that you will be using a mig welder to reassemble your car.

Prime up your seams and fit the panels in place. Make sure your car is sitting perfectly flat and that all your door openings are fitting perfectly and that your convertible top is fitting good, and your window seals are lining up as you go through the process of reassembly. Check your fits frequently, as you do the reassembly. Your starting points for fit is always your fixed body points. The easiest way to maintain that is by making sure your doors are fit to your rockers and "A" pillars before you take things apart. Even gaps at the bottoms of your doors to the original rockers usually gives a good starting point. Keep the doors attached if possible as this with give you the correct position to place your new rockers.

It is extremely difficult to correct problems with fit after a major reconstruction project that you are planning to do, is done improperly.

I have taken on projects like what I just mentioned and did what I could to correct those mistakes that someone else made. It is nearly impossible to end up with a real good finished product after such a thing has taken place though.

Finally, when it is all in place and cleaned real well, seal all the necessary seams with a good urethane seam sealer. That is another thing that we didn't have 40 years ago. Good seam sealer!

Going back to the beginning... If you take your project over to Scott at Benchmark Automotive, located in the business park by Albertsons. You can probably get things cleaned up with his new, wet glass blasting system, especially in the areas that you will be working. You should at least give him a call to discuss the possibilities. Clean metal is far better to work with when doing such a project.

Good luck with your project and don't hesitate to give me a call if you need. I'm over in Sequim now.

Doug

1936 Ford Custom Coach Towncar Sedan Delivery

This 1936 Ford Towncar Delivery has been created from parts that have been collected over the last 40 years. You will hopefully have the opportunity to view it in it's first mock up stage, as pictured here, at the Early Ford V8 meet in Lake Tahoe, the middle of June.

We still have much to do to refine it to the stage of completion, but I have all the confidence that those of you who are experienced in the field of restoration, or design of fine automobiles will be pleased with what you see.

The 36 is being built as it could have been, back in the era that the 1936 Ford was originally conceived.

To go back and see where this project started, click here 1936 Ford Towncar Delivery

We still have much to do to refine it to the stage of completion, but I have all the confidence that those of you who are experienced in the field of restoration, or design of fine automobiles will be pleased with what you see.

The 36 is being built as it could have been, back in the era that the 1936 Ford was originally conceived.

To go back and see where this project started, click here 1936 Ford Towncar Delivery

Early Ford V8 Meet Lake Tahoe 2013 preview 1936 Ford Towncar Delivery

Lake Tahoe will be the location of the 50th anniversary Early Ford V8 meet in June 2013. Larry Hove and I plan to display his 1936 Ford Custom Coachwork Towncar Delivery that we have been building for six years or so.

I have been very privileged to have had the opportunity to work with Larry who has a degree in art and a natural talent and passion for automobile design.

I guess his experience in wood working in the home remodel business has proved to be very valuable in the design and execution of the rear (cargo area) of this fabulous Custom Coach.

This project started out, as I mentioned, about six years ago or so with Larry's vision of using the convertible parts from one of his convertible sedans, and the remains of the Seibert Custom Coach that he had acquired years earlier, to create this 1936 Ford Towncar Delivery.

Larry and I have done some other things together over the years as well. Larry had design input on the 1958 style hot rod 1936 Ford Cabriolet that I built for Phil Blodgett. We also built a custom bodied 34-35-36 Convertible Sedan.

Larry also has a Mullens trailer that we have done a lot of restoration work on. He plans to equip it with some eleven spoke Clev-Weld wheels to match the wheels that will be fit to this car eventually.

Here are a few preview images of the 1936 Ford Towncar Delivery.

I have been very privileged to have had the opportunity to work with Larry who has a degree in art and a natural talent and passion for automobile design.

I guess his experience in wood working in the home remodel business has proved to be very valuable in the design and execution of the rear (cargo area) of this fabulous Custom Coach.

This project started out, as I mentioned, about six years ago or so with Larry's vision of using the convertible parts from one of his convertible sedans, and the remains of the Seibert Custom Coach that he had acquired years earlier, to create this 1936 Ford Towncar Delivery.

Larry and I have done some other things together over the years as well. Larry had design input on the 1958 style hot rod 1936 Ford Cabriolet that I built for Phil Blodgett. We also built a custom bodied 34-35-36 Convertible Sedan.

Larry also has a Mullens trailer that we have done a lot of restoration work on. He plans to equip it with some eleven spoke Clev-Weld wheels to match the wheels that will be fit to this car eventually.

Here are a few preview images of the 1936 Ford Towncar Delivery.

Subscribe to:

Posts (Atom)